For centuries, humans have harnessed the power of the sun. Initially, solar power was used to produce thermal energy like heat or fire. It wasn’t until the late 1800s that scientists discovered that light from the sun produces electricity when exposed to specific elements like selenium or silicon. With more research and testing, the world’s first silicon photovoltaic (PV) cell was created in 1954 by scientists Daryl Chapin, Calvin Fuller, and Gerald Pearson. This PV cell was the first that could truly power an electrical device for several hours at a time. With this basis, solar panel technology was created and became more efficient with every passing year. This leads us to answer today’s question: How are solar panels made?

What’s in a solar panel?

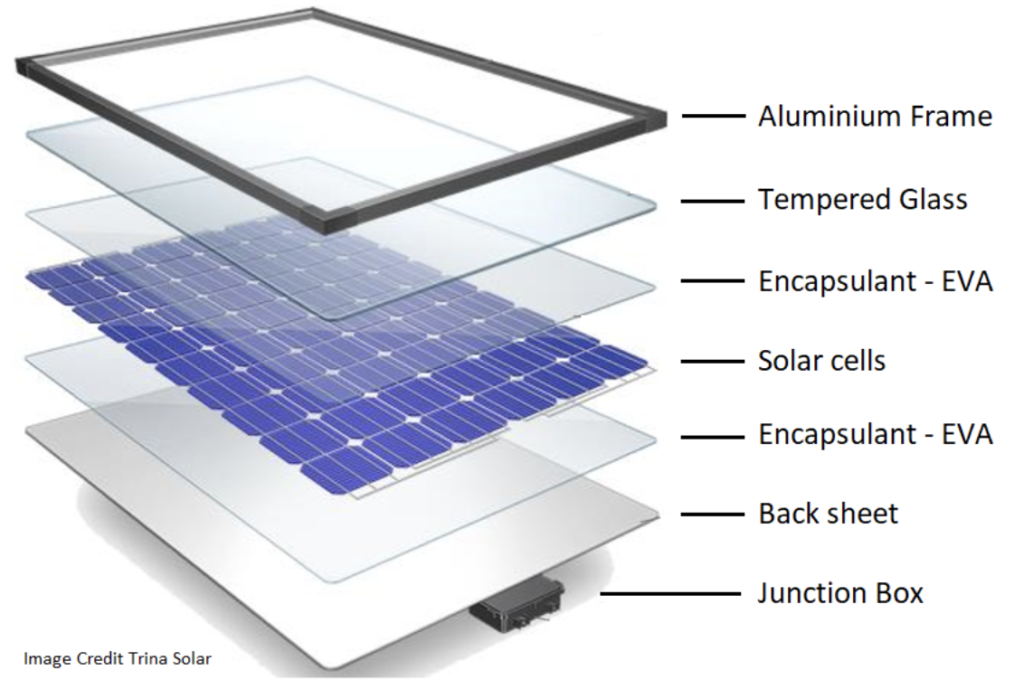

To understand how a solar panel is made, we must first recognize the key components of this renewable energy source. A solar panel is made up of several distinct layers: an aluminum frame, a sheet of tempered glass, a layer of EVA film (aka highly transparent plastic), solar cells, another layer of EVA film, a back sheet, and a junction box. Each layer plays an important role in protecting the solar cells from moisture, dirt, impact, and high wind speeds. This specific combination of layers allows the solar cells to capture light and produce energy at the highest efficiency for the longest period of time. Over the last 60 years, this layering technique has been perfected, and today, solar panels can produce electricity efficiently for over 25 years.

Phases of manufacturing solar panels:

Now that we understand the distinct layers of a solar panel, we can more fully understand how it is made. To simplify the complex process of building a solar panel, we’ll break down the process into 6 phases.

Phase 1: Sand to Silicon

The creation of a solar panel revolves around its most essential component: the solar cells. A solar cell is a layer of silicon cells. Thus, the first step of manufacturing a solar panel is finding raw material to create a thin sheet of silicon cells. Solar panel manufacturers use quartz sand to extract the highest purity silicon. By exposing the sand to very high temperatures in an arc furnace, the impurities are burned away, and large silicon rocks are left exposed.

Phase 2: Silicon Rocks to Cylindrical Ingots

To break these large silicon rocks into large, cylindrical ingots (blocks), the factory turns once again to heat. Manufacturers melt down the silicon rocks in a cylindrical furnace, aligning silicon atoms in the desired structure and orientation. Boron is also added to the melted silicon to give a positive electrical polarity.

Phase 3: Ingots to Disks

With the silicon in the form of a cylinder, workers use wire saws to cut the cylinders into disks or wafers. These paper-thin wafers are very shiny, causing them to reflect light. In order to negate reflection and maximize sunlight absorption, each wafer is soaked in an anti-reflective coating before the next phase.

Phase 4: Wafer to Solar Cell

After being coated and treated, these wafers are now ready to become solar cells. Metal conductors are added in a grid-like matrix on the surface of each wafer, which ensures the conversion of solar energy into electricity. These new solar cells are placed in an oven-like chamber where phosphorus is diffused in a thin layer over the solar cells. The phosphor layer allows the surface of each cell to carry a negative electrical orientation, making a positive negative junction between surface and contents of the cell.

Phase 5: Solar Cell to Solar Panel

The solar cells are linked by soldering a metal connector between each cell, forming 48, 60, or 72 cell panels. The panels then receive their protective layering of a back sheet, EVA film, tempered glass, and an aluminum frame. The junction box is added to connect the panel to the module, allowing electricity to flow from the panel to the home.

Phase 6: Factory to Home

Before solar panels are shipped out to major distributors and homes, each solar panel is tested to ensure that the solar cells perform as expected. With the test passed, solar panels are cleaned, inspected once more, and then shipped out to homeowners across the globe.

For a more in-depth explanation and visuals, watch the video linked below:

Shop Renewable Energy’s Solar Panels:

To ensure the highest quality options, Shop Renewable Energy works with solar companies who utilize third party providers, which allows them to put the most efficient solar panels on our customers’ homes. It is our mission to make homeowners’ lives better, by increasing their reliance on clean and abundant renewable energy, and by providing a world-class customer experience through a reliable sales process and a speedy, high-quality installation.